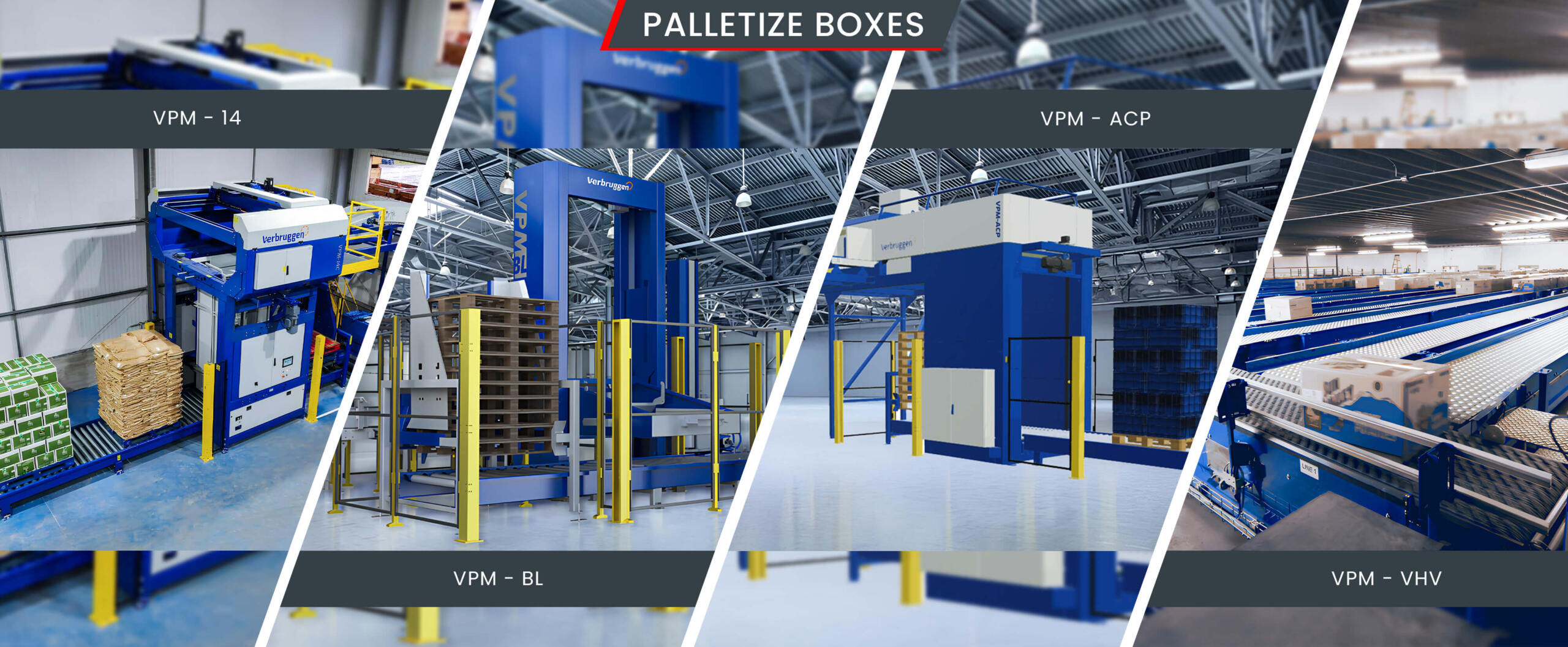

Verbruggen Palletize Boxes

The palletizers in this range are specifically tailored to stacking boxes onto pallets. At Verbruggen we’ve ensured these machines can be used by our broad range of customers. That means both small and massive operations can be facilitated by our state-of-the-art palletizers. As a result, our box palletizers are capable of industry-breaking-records in terms of speed and quality of process. Our VHV, for example, is capable of processing 120 units PER MINUTE. Not just a particular box, but boxes of all packaging types and also including RPC’s and Crates. As always, pallet wrapping, accumulation systems, corner board strapping, fully automatic operations and much more are available options to utilize with your palletizer. Verbruggen box palletizers result in less product damage, a reduction of physical labor costs, elimination of down time, and a faster stacking time. Remember! We provide custom solutions – which means that the machines below are frameworks of layouts that we can build for you. Have you got limited space, and are uncertain if our machine will fit? A challenging issue beyond the specs of the frameworks below? We recommend you still reach out to us – we have got your back, and will figure out the right box palletizer solution for you.

VPM – 14

Palletize with the innovative technology of the VPM-14 and upgrade your bussiness. Fully-automatic stacking at high quality becomes a reality with accurate and overlapping product placement combined with adjustable vertical compression force inside a 4-sided enclosed stacking bin. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

• Consistent & stable pallet stacks

• Fast stacking capability

• Low power consumption

• Efficient operation & low maintenance intervals

• High return & short payback period on investment

Products are supplied to the manipulator by reliable conveyor belts including automatic product buffering. Products will be handled by the special manipulator equipped with center flaps for an accurate product positioning. Horizontal moving formation doors allow each pallet/product layer to be compressed against the formation doors inside the stacking bin while the machine continues forming the next interlocking product layer resulting with the perfect finished product stack.

VPM – BL

The VPM-BL is a low-level compact palletizer using sliding plates to accurately position boxes, crates, trays or bins of various sizes (even very small) on a pallet. The VPM-BL is available at a reasonable price providing reliable and efficient palletizing of box-type goods.

Boxed goods are positioned and accumulated in the infeed section by a programmable stacking pattern. A slide arm then forms the full layer on a formation plate. The layer is enclosed on four sides by a compression collar ensuring that the layer is accurately positioned on the pallet. Compression collars are used once again after the layer has been formed on the pallet, ensuring an excellent stacking result.

The VPM-BL can easily be upgraded from semi-automatic (where the pallets must be placed on the floor) to fully automatic (equipped with an empty pallet dispenser, sheet dispenser, full pallet conveyors and wrapping machine).

VPM-ACP

No Text.

VPM – VHV

Verbruggen’s VPM-VHV palletizer is your leading choice for high-speed stacking of products in boxes, RPC’s or crates. The VHV offers the latest in technological innovations, fast stacking capacities up to 120 boxes/crates per minute, and very accurate product stacking results. The VHV palletizer can be customized and expanded to suit your needs including multiple lines of product accumulation, pallet wrapping or corner board/strapping with fully-automatic operation for optimum efficiency and cost savings.

The VHV palletizer is equipped with specialized infeed conveyors allowing products to be turned and accurately positioned during the infeed process for precise pattern arrangement within each layer. Each layer is pre-formed on a formation plate for maximum efficiency before being compressed within the 4-sided compression collars resulting with a tight, consistent and stable pallet load.

The VPM-VHV is equipped standard with an electric pallet lift. The system includes both electrical and pneumatic component’s, but the machine can also be designed for electrical (non-pneumatic) operation upon request. Users can also easily operate the machine via user-friendly touchscreen. The palletizer is also equipped standard with remote access capability allowing anyone of our service engineers to access your machine for prompt service support or troubleshooting diagnostics if needed.