Project Development

In the development of projects for the processing of potatoes, carrots and onions and other vegetables, we see significant trends worldwide. We have formulated clear criteria for this. These criteria, labor saving, logistics, finidsehd product, integration and commucation, calculations and project panning are separately detailed and explained on this website. These criteria serve as a guideline for us in the development of every project proposal for our customers worldwide. There are no small projects at Allround. At this point we would like to draw attention to a few things that we have to deal with in our daily contact with our customers. When a greenfield project is developed, it is important to realize is our project really on the right place. We have created an interactive map with some arguments that one could consider. The world is not unambiguous. As mentioned, Allround is in the middle of the world. To this end, we have gathered a wealth of information from our dealers and partner companies. We are aware of the latest trends worldwide in packaging and processing. We at Allround are very intensive in the development of data management. The margins in our sector are often thin. So we will have to monitor the process closely. When it comes to washing installations, it is no longer just the installation that is important. We can also advise you in the field of water management and water purification. In all our projects, however, we are always aware that we are working on a distribution solution. Whether we are for the industry, retail, whole sale or farm level, it is essentially a distribution issue.

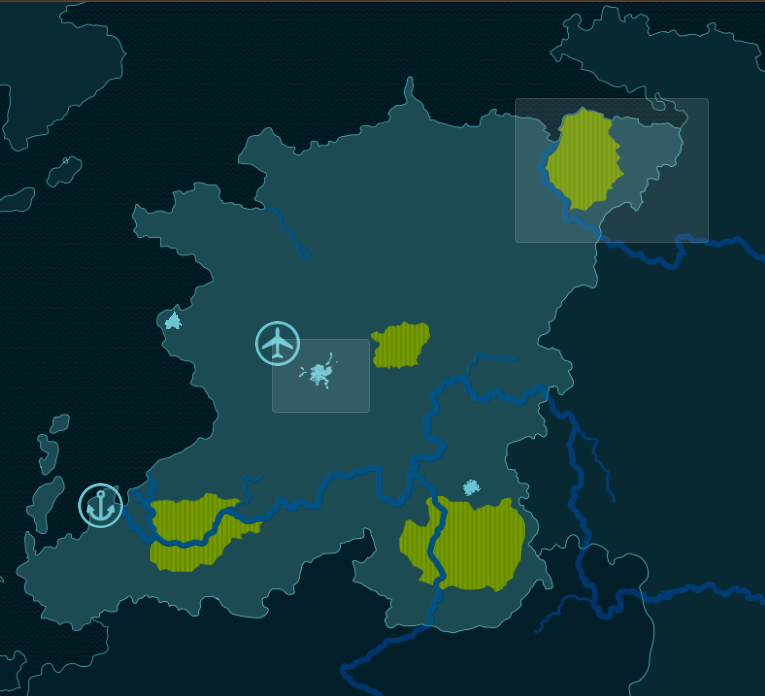

The Product Flow / Location for your project

Think Global Act Local

We at Allround India and Allround Holland have a very broad network all over the world. We do have more then fifty dealers and work togher with more then ten partner companies. We very often see ways of processing, packing and distribution that are determined by local cultural preferences. You come across strange phenomena. For example, onions packed in mesh bags are sold in Israel when they are imported, but not when they are Israeli onions. In Mexico, they want the carrots to be stacked neatly straight on top of each other in twenty-five kg bags. In Brazil, the carrots are neatly placed in trays. In the case of Egypt, a growing share of production is destined for export. In America, paper bags for packing potatoes are popular, in the Netherlands we pack them in the cheapest poly bags. In India, we bought at least five hundred packaged onions, potatoes and carrots. The conclusion is that India still has to go through a development if it wants to meet the international standard of beautiful and fresh potatoes and vegetables in the retail channel. What is certain is that the criteria we have formulated – Labor saving, logistics, finished product integration and communication, calculations and project planning are essential throughout the world. It doesn’t matter if you are farmer, wholesale dealer, industrial or whatsoever. Together with our dealers and partner companies, we try to highlight the things that stand out in a positive way in a certain market to our other customers. In this way, we hope to work with you to come up with new and surprising insights and product solutions.

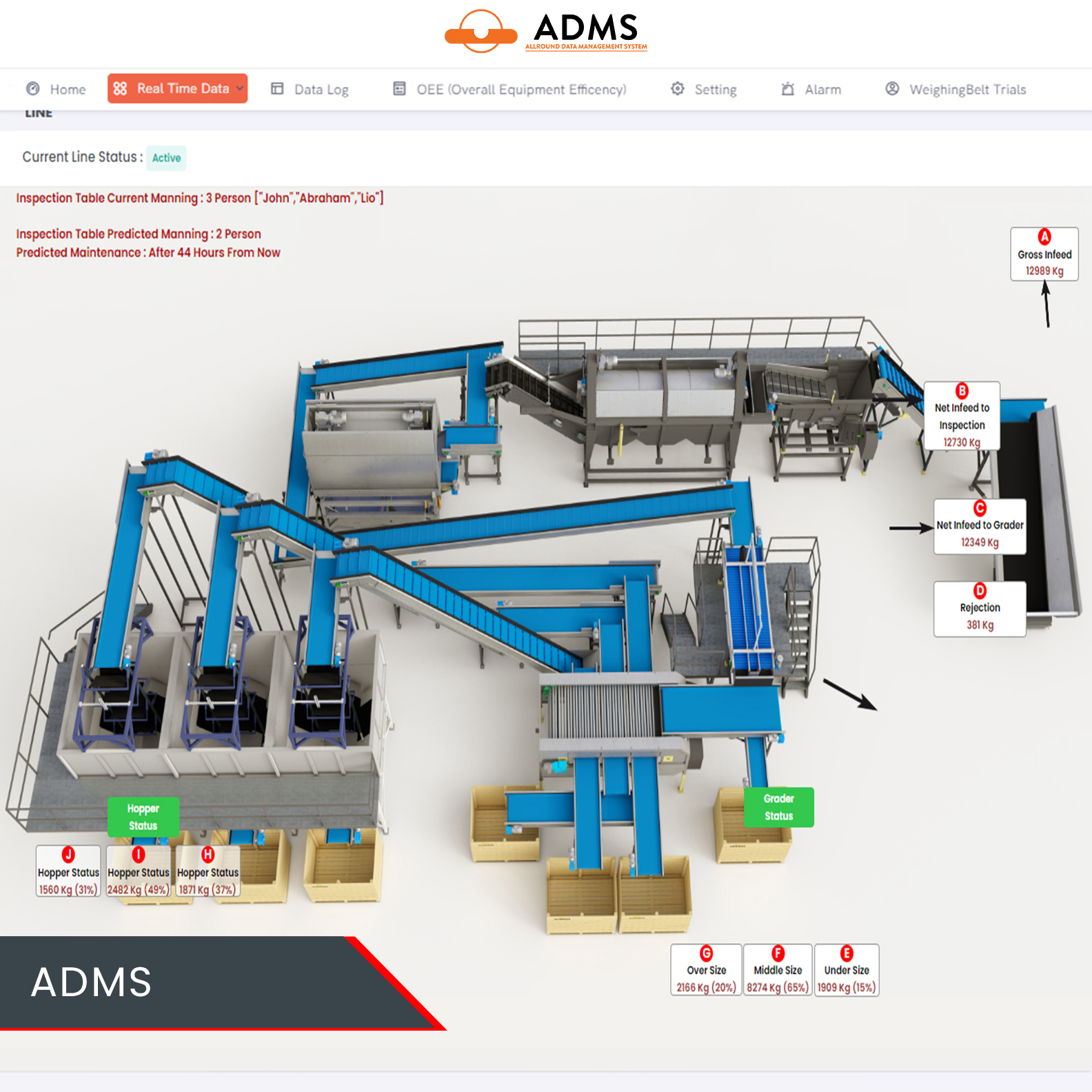

Allround Data Management System (ADMS)

Allround Data Management System is a management tool. With the support of ADMS, the process can be continuously monitored in whole or in part, if desired. When implementing ADMS, we place weighing belts, sensors, electricity meters, water meters and cameras in the line where necessary. Together with you, we determine which values of a particular batch of product and process data need to be measured. The results of ADMS are sent to your ERP or other administration system.

For example:

1. How much soil comes from the field to the processing site. In other words, the supplier adheres to the contract with respect to tare.

2. What is the consumption of fresh water and how much water is recycled.

3. What is the product disapproval rate? How many people do I have to carry out the manual inspection with. Is this following the agreement with the supplier. Is this in line with other years?

4. What is the grading picture of the party? Do the sizes from the grader correspond to what we expected. Is the composition of the party according to the contract.

5. How many people do I staff the entire process? Is this in line with what is normal? Do we deviate from previous years with the number of employees. Are we not out of step with the competition? Where can we act more rationally?

With ADMS, the whole batch is the sample. You’ll never have to argue with the supplier again. The results can be administered per hour, day, month, season or year wise. With this data systematically available, a real benchmark can be established. We are now able to make workable agreements with suppliers and staff. You can use this data to compare different locations of your company.

Water management

Over the past decades, we at Allround have installed hundreds of washing installations all over the world. The circumstances are very different. You’re sometimes dealing with very different seasons. For example, severe frost. In other places, water is very scarce. Even in places in India where there is apparently enough water, water must be handled with care. After all, you can’t extract unnecessary water from the groundwater indefinitely. You also can’t keep discharging dirty water indefinitely. As companies, we will have to take responsibility for the environment and the living environment around us. We at Allround make a complete water management schedule for you. Here it is clearly indicated which provisions you need to make in order to connect the washing system without any problems. We give clear instructions on which inlet and outlet pipes and/or gutters you should use. Where complete or partial purification (e.g. organic waste seperation) of the rinse water can take place. See also the section on partners Taneco with water treatment plants.