Potato – French fries, Chips, Flake, Namkeen and samosa

Allround and it’s partners are prominent suppliers for the potato process industry. In principle, the lines and technology of Allround and partners are separate from the actual frying line. Allround with the Partnership of Companies is therefore compatible with any producer of French fries, chips or whatever. However, we can offer internal transport for you for each project, installation or single line. Below is a brief overview of our delivery program for potato processing projects

Product range for retail for washing, sorting and grading lines.

- Box tippers.

- Receiving hoppers.

- Pre cleaning sets Blank rollers, spiral rollers, spiral with blank rollers & finger rollers.

- Washing machines. From 1 cubic meter content till 18 cubic meter content.

- Onion toppers. Optional with pre grading.

- Sorting tables. Roller inspection and flat belts.

- Grading machines. Radial grading shake grading machines, web graders.

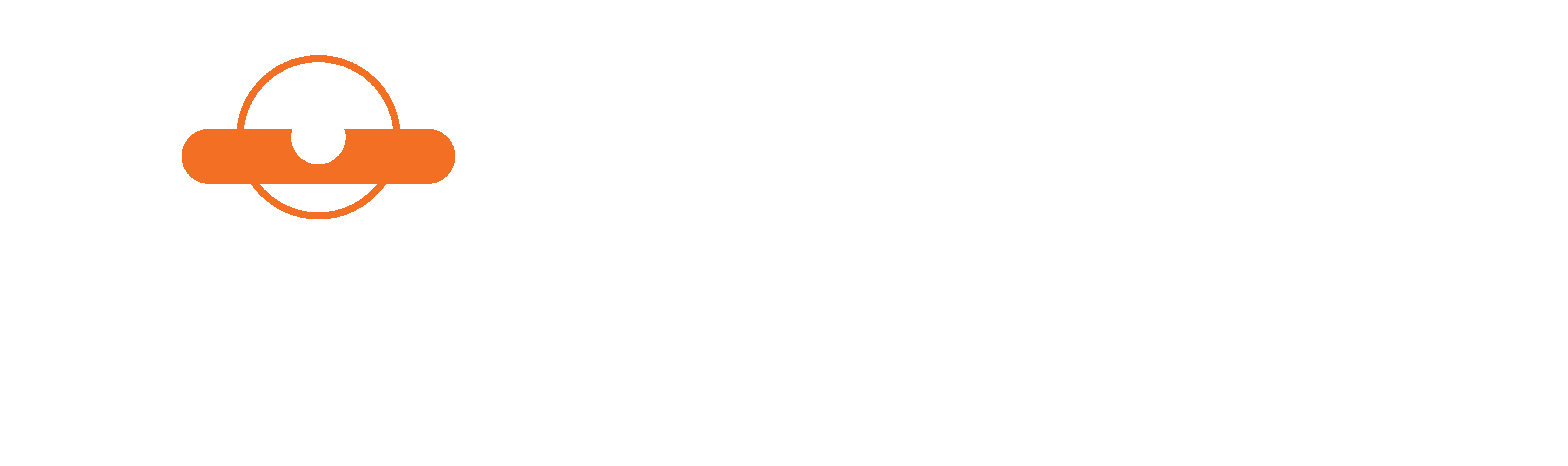

- Leaf separators

- Evenflow Hopper

- Dust extraction.

- Water purification systems.

- Internal transport

For the reception of three tons to one hundred tons per hour or more.

For the reception and supply of potatoes to the factory, we basically have two forms. The factory receives the desired amount of potatoes from the suppliers every day or it chooses to store its own potatoes. Bulk storage is usually chosen for storage purposes from a cost point of view. Allround has a complete range of cold stores and handling equipment. See the Allround Storage directory here. For the receipt of potatoes from suppliers, the most common for bulk receipt are: live Bottom trucks or tip trailers. Often, they are also supplied in big bags, cubic boxes or 50 kg jute bags. With this form, it can be fed directly to the line. With a storage hopper as evenflow, or the potatoes are first transferred into cubic crates. The Allround radial grader is often used as a pre grader. Weighing belts can show real time the flow rate of product but also waste, soil and rejections. Depending on the circumstances and budget, we can present various options for your product and waste flow.

Grading – Temporary storage – Blending

After receipt, the potatoes are graded and collected in so-called storage – even flow hoppers. Before or after grading, the potatoes can be manually inspected, possibly in combination with an electronic sorter. The shake grader can be placed both on the ground and above the bunker installation. The bunker installations have a dual purpose. First, it’s a big evenflow. It ensures that the production line(s) always have a constant supply of sufficient potatoes. The evenflow function of the storage hoppers is to ensure that the difference in capacity of the receiving bunker, washing line and production line runs smoothly. The storage hoppers are usually equipped with fall dempers and ventilation. The sorted product has now been collected in different sizes. If desired, the weight per bunker can be read in real time. With the help of the weighing belts and the Central Control System, perfect blending can now be made. With the help of the program, the blending can be determined in percentage terms. The storage hoppers with rejected product can be emptied individually. Allround has installed dozens of large and smaller bunker installations in the last few years. machine In collaboration with our partner Taneco, we can also offer you a water purification system. Taneco’s systems are used at many chips and French fries factories.

Destoning – Washing – Leaf separation

Allround has been active in the washer market for more than thirty years. Starting with the washers for tulip bulbs, we have expanded our program to vegetables and potatoes. The washers for potatoes only have specific requirements. With large capacities, the construction must be heavy. The type of washing machine and the size of the drum depends very much on the conditions under which the harvesting takes place and the degree of soiling. Many times two stages of washing is required. Allround started with octagonal drums but now prefers the round drum in its drum washers. We have an integrated destoning drum washer. A perfect solution for a very acceptable price. We can offer different types of destoners, both cyclone destoner and propellor destoner, leaf separators and polishers in different capacities. We have also supplied mobile washers for various groups of growers to supply the potatoes washed to the factory. Of course, all machines are on request available in stainless steel. The delivery program includes washing lines from two tons per hour to more than a hundred tons per hour. Optional the washing machines can be executed with an auger to get rid if the slurrythe machine In collaboration with our partner Taneco, we can also offer you a water purification system. Taneco’s systems are used at many chips and French fries factories.

Internal transport – Weighing belt –

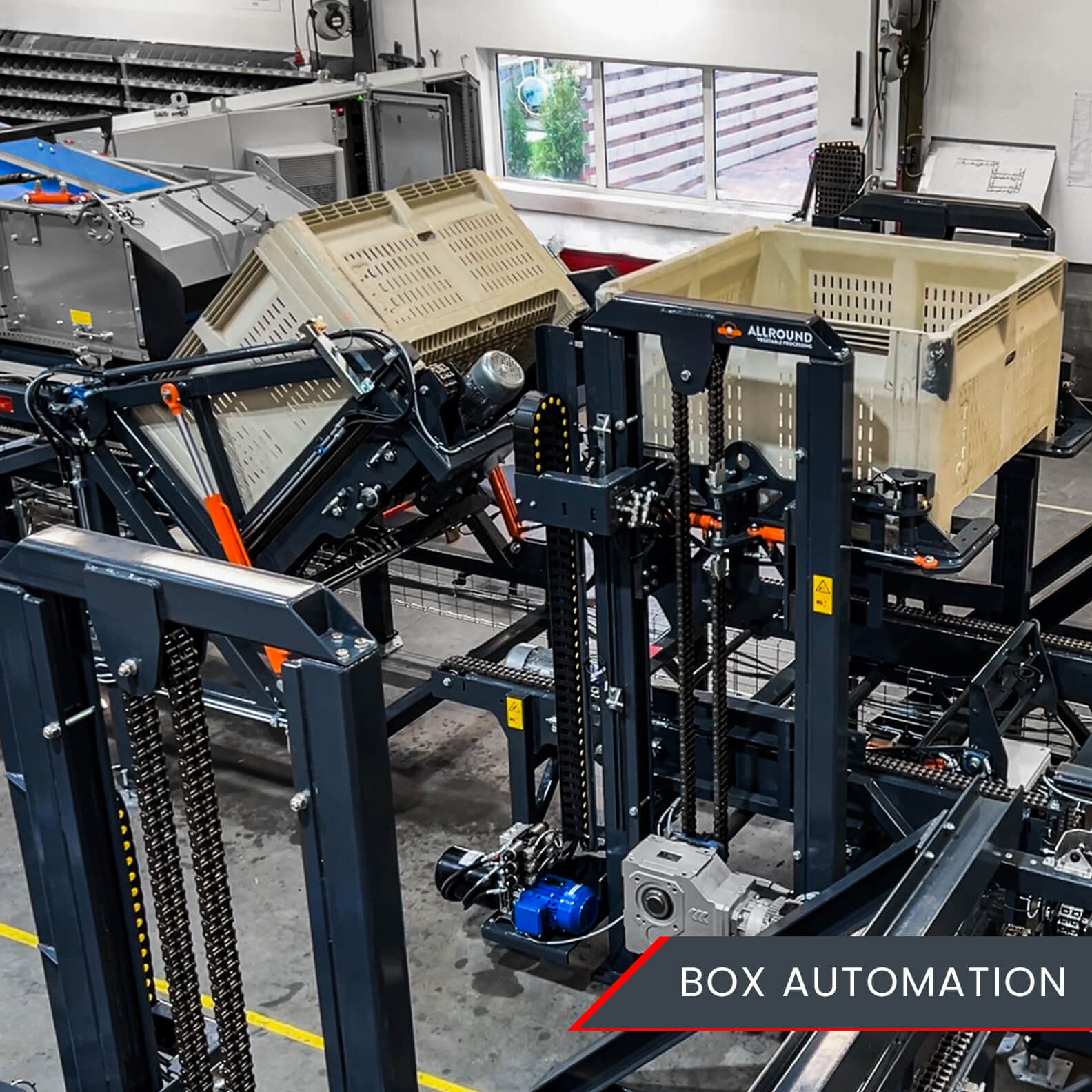

Box Automation

Allround is very aware that internal transport is the aorta of your project. To this end, Allround is perfectly equipped with a full team to develop smart and cost-efficient internal transport systems for you. We always analyze carefully in order to get the product to the right place as much as possible without the intervention of human handling. We have a very diverse range of conveyor belts in our program. For heavy work, we have rubber trough belts. Ranging from 60 cm wide to 100 cm wide with or without knick. Different types of flat belts depending on the load to be transported. We also make weighing belts and smart transport belts. The weighing belts are used for administration only. What has taken place, how much waste or second quality has been removed from a particular lot. With the smart belts, the belt can adjust the speed of the amount of product according to the need of the process. For example, in blending, this is an essential part. You want to get exactly the percentages entered for the production lines. We can also offer you all sizes of modular Intralox belts. both straight and radius belts.