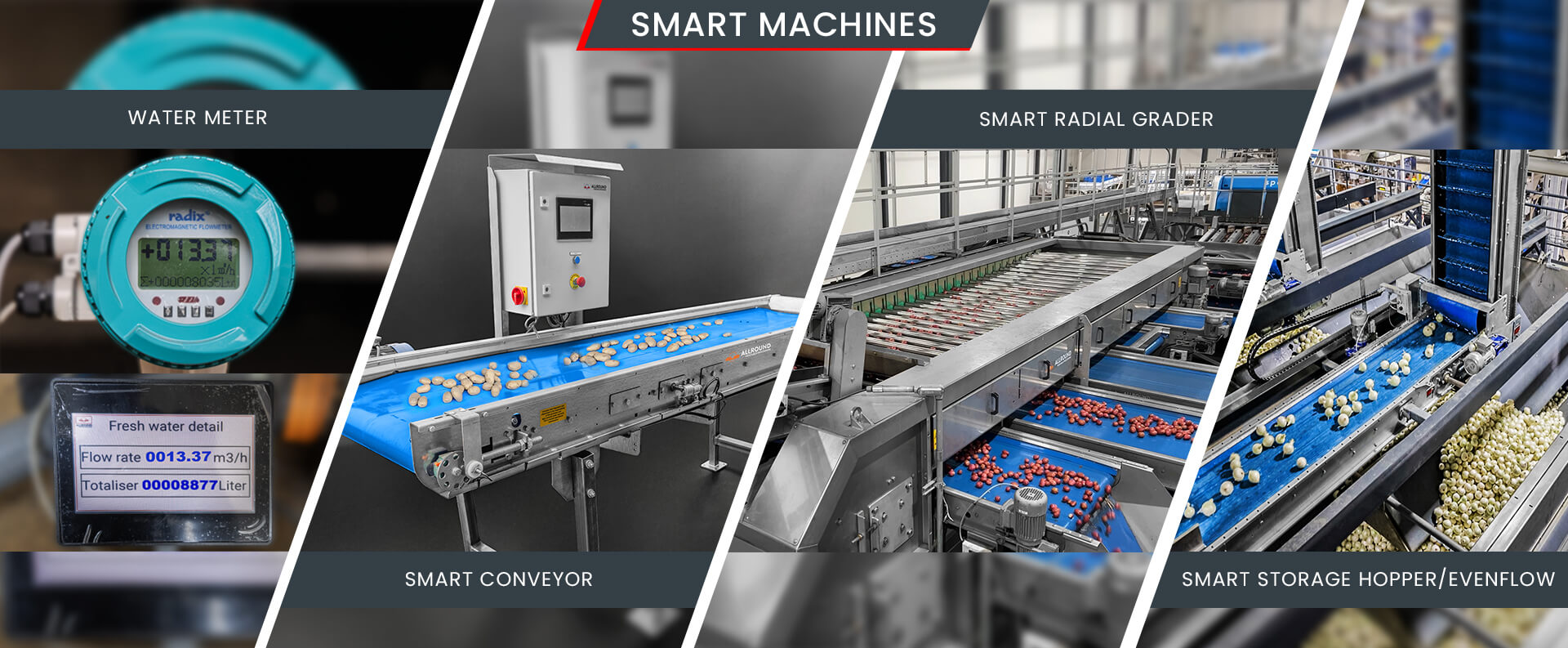

Smart Machine

e at Allround Vegetable Processing want to make our machines, lines and integrated projects as smart as possible. By Smart we mean that the relevant data will be generated from the machines, lines and projects. This data must be translated into useful information for management. If necessary, we want to show all data in real time in a dashboard for the line manager. Where in the line/project deviations in the process take place. In this way, we want to enable the line manager to intervene immediately if possible. When dealing with different suppliers, it is of paramount importance to monitor each party. To do this, we work with big data. With big data, the entire batch or process can be regarded as a sample. For example, it is possible to keep the supplier of the various phases in the process informed online in real time of what he is really delivering. For example, how much soil, stones and clods a certain batch of potatoes has. After washing, show how many people there is and how many people have to do the final inspection. All this data can be directly compared with the agreements that have been made between the vendor and the buyer. Both per year and from the supplier in question as well as from the entire history with all suppliers. In the paragraphs below we show you some examples which enable us to do so.

Weighing Kit

It is possible to build in a weighing kit for certain existing Allround transport conveyors. After analysis of the construction, conveyors from other suppliers it might be possible too. With this application, the flow of product per hour can be measured. The weighing kit also gives the cumulative value. So you can set when you want to know the total value of the conveyor. You set zero anytime with the weighing kit. Converting a normal conveyor belt to a weighing belt is not easy. You have to deal with conveyor tension. Slip factor is also an important value. In other words, we need to be evaluated case by case.

Smart Conveyor

The smart belt can be set to supply a certain amount of product. For example, to mix a percentage of a certain size together. The smart conveyor can also be used in combination with an actuator in a radial grader to make a desired amount of product. The smart conveyor not only weighs, but also reacts to the outcome. For example, if you want to feed 2000 kg of a certain product proportionally, you can set this. The smart conveyor can be used for many applications.

Smart Radial Grader

The radial grader is a grading machine that works on the principle of receding rollers. The radial grader grades by the smallest size of the product. The radial grader can be used to grade a wide range of products. With the smart radial grader we can set what percentage of the total output we want to have in a particular grade. In other words, we make a certain grade. With the help of the smart belt and the actuator in the radial grading machine, we stretch the grade in such a way that we get the desired distribution. This option can be a very useful and profitable application for retail packers. For the process industry, the Smart Radial Grader can be used for blending. You make the world a little bit more ideal.

Smart Storage Hopper / Evenflow

The Allround Smart hopper has been specially developed as a very large even flow hopper. The Allround smart Hopper combines the advantages of a storage hopper with an evenflow hopper. The Allround Smart Hopper is suitable for the most sensitive products. For example, the Smart Hopper is used for onions with a very thin skin, such as in the USA. The Smart Hopper is filled with a horizontal belt in combination with a vertical filling belt. The output of the product is done with two conveyor. The second conveyor at the exit runs faster than the first, ensuring an even output. There are no more valves in the Smart Hopper. The product always goes out of the bunker to the packaging machine or industrial process without friction. The Smart Hopper can be adjusted in speed in all possible ways. The build-up of the product in the hopper takes place in layers of approximately twenty centimeters. The Allround Smart Hopper can be offered in size according to your needs and space. We would like to invite you to see if these unique storage / evenflow hoppers in your business operations can also provide an answer to a complex logistics issue. In combination with the calculation examples that we have and make, we come up with the most amazing results and suggestions.