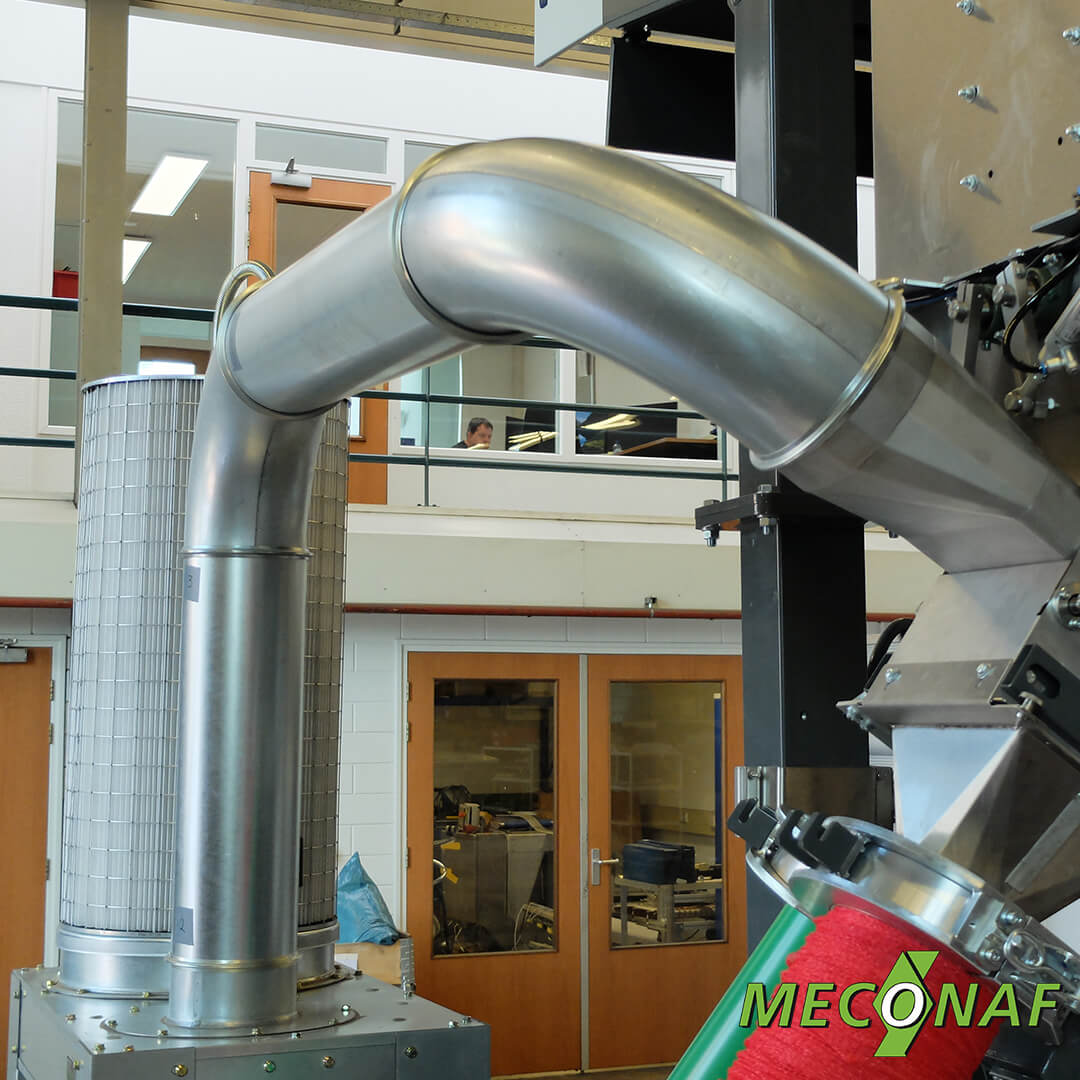

Extraction system for optical grading and packing

n the processing of onions and potatoes, the machines are getting more and more sophisticated, and equipped with electronic part, like load cells, camera systems, complete cooled rooms for the electrical switch boxes. Dust and electronic equipment are not a very good match. It can damage the equipment, it can give ware to the machinery (parts that turn like bearings and chains) and can cause malfunction of the equipment (bad visual for the camera)But also skins can form a big problem for the machinery. It can clock up the sieves of an onion topper, it can cause problems at the clippers underneath the weighing machine and it can also make the product look bad for selling. Both skins and dust are causing a bad environment in the area where the machines are processing. In this same area people are working. Extraction will give a cleaner and healthier environment for these employees. This is also the case when plastic net-bags are sealed. The smoke coming from the burned plastic needs to be extracted.

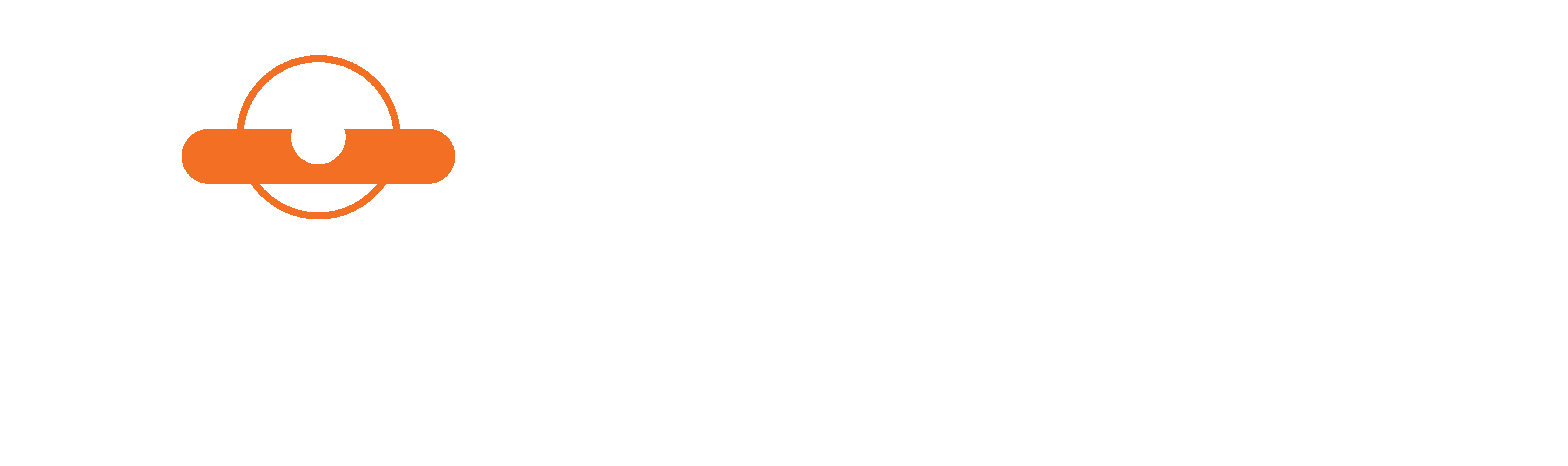

Optical Grading

The optical grading machine is more and more common in the processing for onions and potatoes. This grading equipment is related to the grading machines for apples oranges and so on. Those products are clean and don’t loosen their skin during processing. When we are grading (seed) potatoes, there is a lot of dust spreading around. This dust must be extracted. The optical grader is driven by a chain which is greasy when dust is mixed with this grease it can ware the chain more quickly. The product itself is running over the machine in a cup which is attached to the chain. It is transported underneath a camera system, where it is check on quality. This area where the camera are mounted needs to be a very clean part of the machine, The images can be unclear when dust is floating in this camera box. When grading onions on a machine like this it is the same issue with dust as described above. A second problem can be caused by the skins. Skins can give a false image by the camera system. Skin can also fall down and drop onto the chain which makes the chain dirtym

Weighing and Packing Machines

Weighing machines are full of electronic equipment and moving part. This is also existing at the packing machines mounted underneath the weighers. We built dust tents over the weighing machines when we are packing unwashed potatoes or onions. It depends what kind of weighing machine is used and placed underneath the weighing machine. There are so many different type and brands of weighing systems on the market. With our experience we know what kind of extraction is needed on these different weighing machines. This is also the case with the packing machines. This often the last place to take out skins and dust with extraction. If it is installed the right way, we can achieve a nice and clean product. Taking ride of the skins and dust will prevent a lot of wear and the area is much cleaner. It is also a much better working environment for the people working in the packing area. With a good extraction you will have less sick leave of your employees.

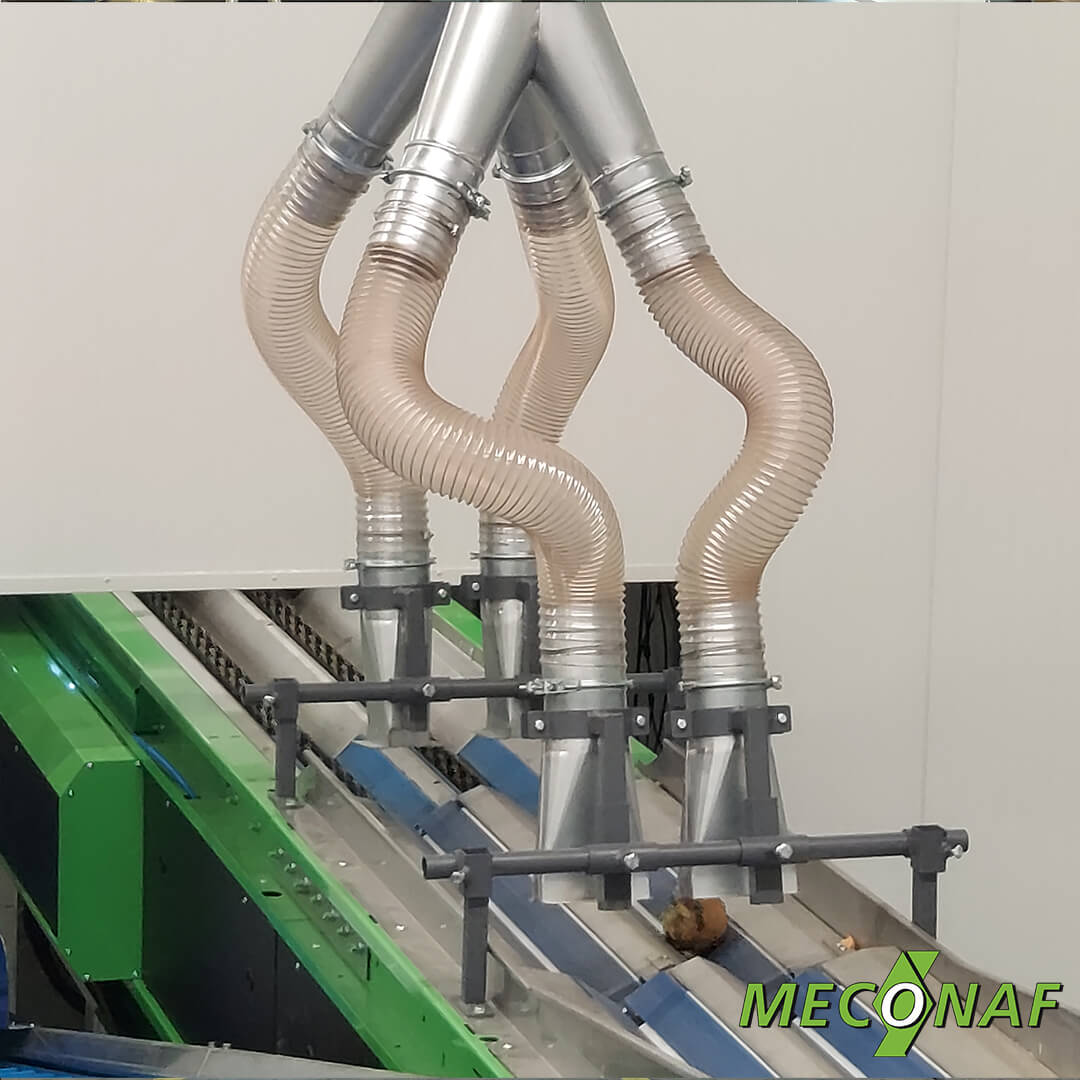

Clippers

Product is packed in a lot of different ways. Plastic bags, paper bags. But still a lot is packed in plastic net bags. From 0,5 kg till 25 kg, and even sleave package where 3 or 4 onions are packed in a row. The packing into the bags is not a problem. The difficulty is to close the bag. It is done with a steel clip which is pressed around the net bag on both ends or only on the top. It is done with a clipping device, a so called “clipper”. The problem is that when there is a skin between the clip, it will not fully close around the bag. The bag is rejected and needs to opened and the onions need to be packed again. It is a loss of packing material which is a loss of money. Another problem is that the onions will fall out of the unclosed bag and fall on the floor. This gives a lot of extra work to pick them up again and onions can be damaged to. From experience we hear that it can go up to 10 to15% of the bags which are not fully closed. With a good extraction where we take out almost all the skins this number can be lowered which will save al lot of extra work and money.

Seal Smoke

Another way of packing onions or potatoes is in a larger net bag. The net bag is delivered in a large roll. The material is in a double layer. With a heating device the side of the bag is melted to each other. Than the bag is filled. When the right amount of product is in the belt the top is sewn up. At last the final part of the bag is cut with a hot knife to loosen the bag from the roll. With both melting devices smoke is coming from the plastic material. This smoke is toxic, and very unhealthy for the people working is this area. The smoke can be extracted with an extraction system . This is always a separated system. You cannot combine it with the dust and skins extraction system. The smoke of the sealing process is greasy and cannot be combined with dust. It will stick to the extraction ducts and can cause a blockage.