Mechanical Grading

Allround has four different mechanical grading machines in the program. The four different machines of Allround, radial, shake, web and string, are explained in more detail on this page. However, there are multiple ways of grading and pre- grading. In the context of this text, I will touch very briefly on the advantages and disadvantages. Grading manually. Disadvantages: very labor-intensive. Organizationally problematic. Need a lot of space. A routing is difficult to make. No uniform grading. Optical grading. Advantage is internal and external quality control. If things go well, you no longer need manual control. Disadvantages of optical sorting for potatoes and onions are: machine has a large footprint, machines are expensive, high maintenance costs. Not all onions and potatoes can be checked internally as easily. Onions and potatoes with a thick skin are problematic. For each party you have to set the parameters. Operation is quite complicated. The third way is electronic pre-sorting. These machines do not sort by size or weight. The machine sorts out waste and/or second quality with very high capacity. This machine saves directly on labor. Machine has a small footprint. The disadvantage is that not all products are easily sorted. The result depends on the skin and degree of pollution. For each machine, the individual conditions determine the effectiveness. We work all over the world with all manufacturers of both electronic and optical sorting machines.

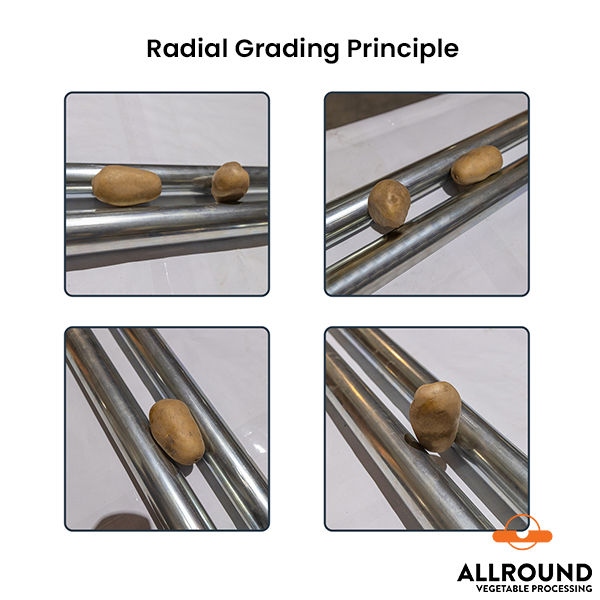

Radial Graders

The Allround radial grading machine is a world leader. The principle of the radial grader is the receding rollers. Damage to the product is minimal. We make the machine with a grading width of 80 cm to a sorting width of 300 cm. The number of grades and the minimum size and maximum size differ per customer. The size setting can be supplied electronically or manually, the machine is also used as a pre-grader for the onion topper or as pre grader with an optical grader. We can also sort out very large products. For example, rutabaga. The Allround Radial grader is also available in a smart version. In this version, the input belt weighs the total input. All output belts indicate the percentage and weight of the specific grade in real time. The percentages that need to be made for your order can be set in this way. Together with you, we determine the correct execution of your radial sorter on the basis of the product to be sorted, the required capacity and the specific market requirements.

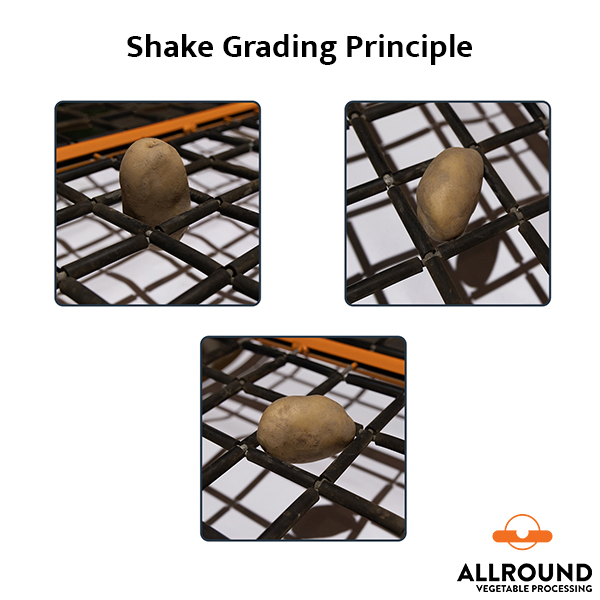

Shake Graders

At Allround we have a full range of shake graders. The SG 60, SG 80, SG 120 and the SG 160. The shake grader grades by square’s size. The product is therefore graded to the largest size. The grading range is from 15 mm to 85 mm. The shake grader is mainly used for potatoes and onions. An additional advantage of the shake grader is that the largest products are the shortest time on the machine. At Allround we have driven the shake grader in a modern way using a crankshaft per grade that are connected to each other with a timing belt. With this drive we have a completely silent and virtually vibration-free machine. The drive is infinitely adjustable in this way. The grading decks are very easy to change. The grading decks are available in full rubber for smaller sizes. The larger sizes covered with rubber or not covered. Depends on the size. The machine has a small footprint because the grades are on top of each other. The shake grader is also available in a smart version. Here the input and output belts are executed as weighing belts.

Web Graders

The third way of mechanical grading is the web sorter. With the web grader you can grade four-jug eight-sided (hexial) and round with this you can achieve the highest accuracy. Allround makes web graders with a working width of 80 cm to 140 cm. The machines can be expanded per grading section. The webs are made of rubber. The web grader is widely used in potatoes and in onions. The largest products, biggest grade, is the longest on the machine. Especially with onions, this can be a big disadvantage. Changing the webs is a bit of work. At Allround we have made it relatively easy. The size and number of grades is always determined according to the specific wishes of the customer. The machine has a relatively large footprint. The machine gives the highest percentage damage as compared with radial grading and shake grading.

String Graders

In addition to these three categories of grading, Allround has various other forms of (pre)sorting. The string grader for onions, a very high-capacity pre grader. The machine works on the principle of longitudinally placed receding strings. The machine is electrically infinitely adjustable in size. This way of grading does not damage at all. The Allround string grader is mainly used as a pre-sorter for several onion toppers. The machine has a small footprint.

Another form of pre-grading is with a roller set. The roller set can be mounted on the receiving hopper or as a standalone. The main function of the role set may be to sift out as much soil as possible. For this we have a special roller set in which a steel roll is alternated with a spir rubber roll.

The roller sets for undersized sorting are available in a range of rolls, from blank rolls to diabolo rolls. As a standalone, the number of roles is negotiable.