Manter offers a diverse range of packaging machines for the agricultural and food sectors, with expertise in designing and implementing complete packaging lines tailored to specific needs. These packaging machines accommodate various bagging options, such as net & mesh, PE & PP, paper, pouch, block bottom, and pillow bags. For transportation purposes, Manter also provides baling machines to pack multiple consumer bags into master bags made of mesh, burlap, paper, or PE. Additionally, they offer packaging machines for punnets, clamshells, and flow wrapping.

Rollstock Baggers

Manter offers a variety of Rollstock Baggers, including multiple variations of the RSB-P and AutoMesh. The RSB-P produces bags from clear film, sealed with either a seal or tape. The clear film bags can accommodate weights ranging from 1 to 15 kg and can be perforated to allow airflow to the products inside. Depending on the product and packaging requirements, these bags can be customized in terms of size, type of closure, perforation, and exterior presentation. The Rollstock Baggers are highly versatile, with a capacity of up to 40 bags per minute for 1 kg bags, making them an efficient solution for various packaging needs.

The AutoMesh(+) create bags from mesh material and closes them using a sewing head. The AutoMesh+ has a lot more convenience features such as automatic adjustment of bag separators and fill opening. Both these Rollstock baggers have a weight range of 2,5 to 25 kg and a capacity of up to 14 bags per minute with 25 kg bags. Their breathable nature makes them ideal for packaging fresh produce such as potatoes and onions.

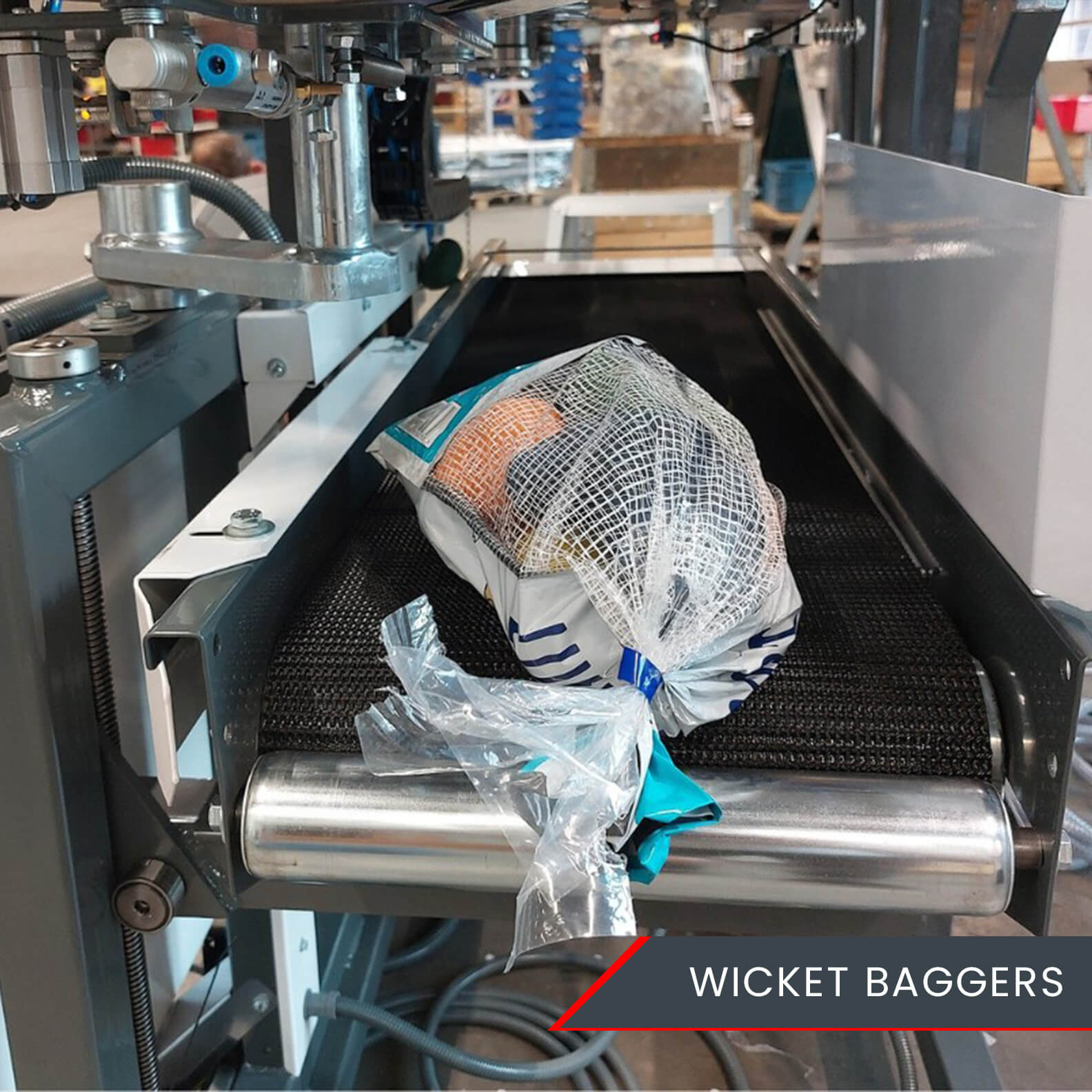

Wicket Baggers

A “wicket bagger” is a type of packaging machine used primarily for automatically filling and sealing bags. The machine is designed to work with wicketed bags, which are pre-opened and grouped together on a wire or plastic wicket to allow for easy handling and efficient automated filling. Manter offers Wicket Baggers in Single and Double configurations, including the SF (Soft Fill) and Ca (Carrot) model. They are perfect for quick and efficient bagging of produce. With a max. capacity of 60 bags per minute and weight range of 1 to 10 kg these relatively small machines are very flexible and highly productive. These machines are designed to handle pre-made wicketed bags that are mostly closed with a Kwik lok or tape.

Pouch Baggers

Manter offers Pouch Fillers in both regular and Soft Fill (SF) configurations. The regular Pouch Filler is versatile and commonly used for various types of citrus fruits. In contrast, the SF configuration is specifically designed for apples, ensuring gentle handling to maintain their quality. This packaging provides a luxurious appearance with features such as zip closures, making it a premium option compared to other packaging types. The machine accommodates a weight range of 0.25 to 2.5 kg and can process up to 20 bags per minute, making it an ideal solution for small, high-end packaging of fruits.

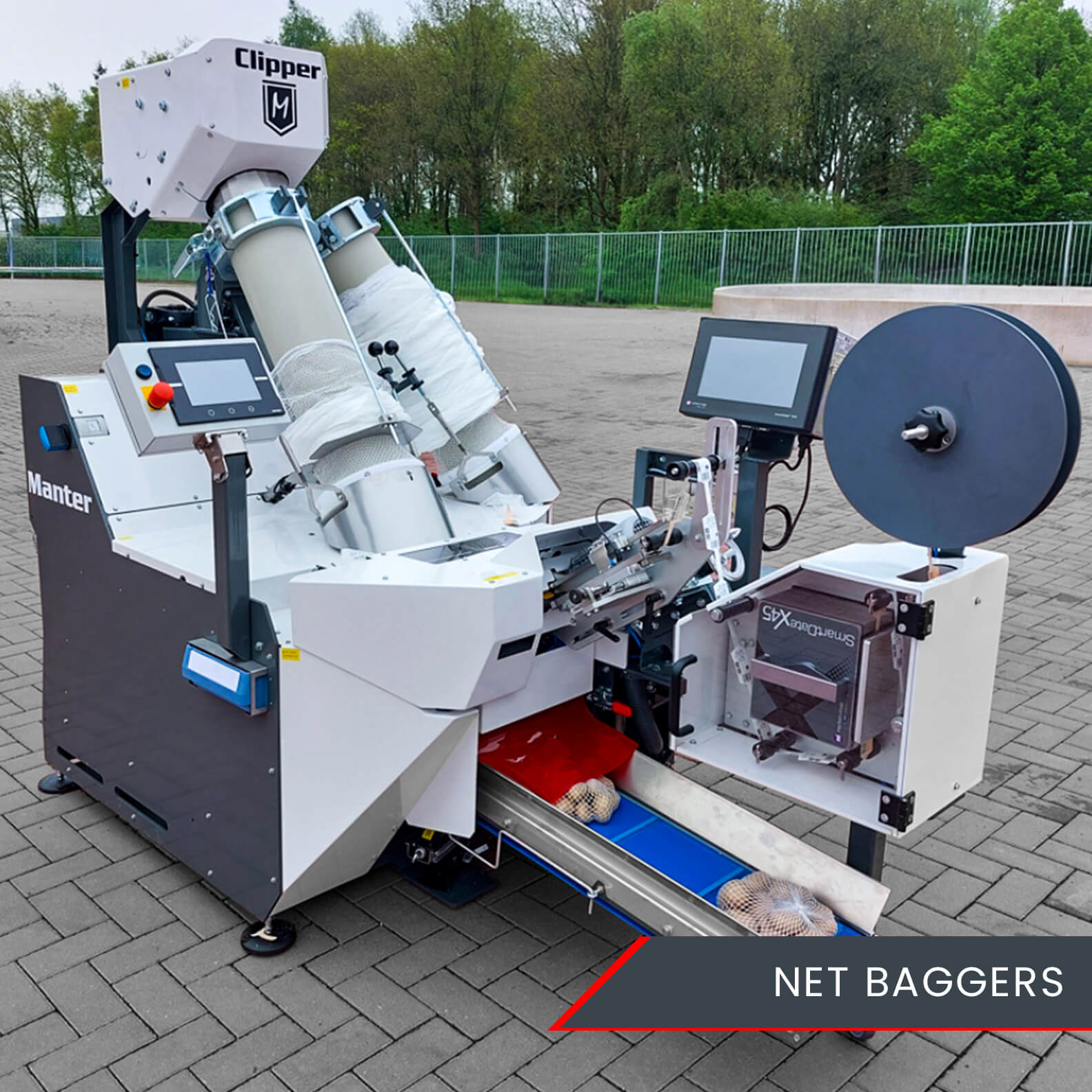

Net Baggers

The Mono Clipper and Clipper M3 Net Baggers are specialized for packaging fresh produce in tubular net bags. These machines provide a sturdy and breathable packaging option that keeps products fresh while being visually appealing. The MoNo Clipper produced mono material bags that are easy to recycle, while the Clipper M3 has a higher capacity of up to 55 bags per minute, using clips in stead of a heat seal.

Paper Baggers

Our Single and Double Paper Baggers are designed for eco-friendly packaging solutions. Designed in full compliance with CE standards, this machine meets stringent safety requirements. The paper bags can be completely printed on the outside and they often include a cellulose window and a handle. The weight range is 1 to 10 kg and the capacity of the ‘Double’ version is 30 bags per minute. The Paper Baggers offer a sustainable alternative to plastic packaging, aligning with increasing consumer demand for environmentally friendly options.

Punnet & Clamshell Fillers

Punnet and clamshell fillers are specifically designed for delicate produce such as cherry tomatoes and small fruits. These machines ensure precise filling and gentle handling to maintain the quality of the products. They are compatible with various container sizes and types, offering a versatile solution for growers and packers. With a weight range of 0.25 to 2.5 kg and a capacity of up to 44 packs per minute, these machines are ideal for packaging facilities that require high production efficiency without compromising on product care.

Flow Wrappers

VFFS (Vertical form fill seal)

Vertical form fill sealing machines, such as the VT 500, VT 2000 ML, VT 6000, and VT 6400, belong to the ‘VegaTronic’ series by IMA Ilapak. These machines range from entry-level to the most advanced options available, offering both intermittent and continuous motion capabilities. Designed specifically for packaging fresh produce, they accommodate a variety of film-based packaging including; pillow bags, block bottom bags, carry fresh bags, doypack, quatro seal and Easypack®. The VegaTronic series ensures high-quality sealing and efficient packaging, accommodating various packaging styles to meet diverse market demands. With a weight range of 0,1 to 5 kg and a capacity of up to 80 bags per minute, the VegaTronic series ideal for packaging facilities who require a high degree of flexibility and speed in their packaging processes.

HFFS (Horizontal form fill seal)

Horizontal form fill sealing machines, or flow wrappers, are available in three series: Scorpion, Panda Red, and Panda. The Scorpion series is the entry-level option, offering reliable performance for basic packaging needs. The Panda Red series caters to mid-range requirements with enhanced features and capabilities. The high-end Panda series delivers top-tier performance, suited for complex packaging demands. Depending on the product, packaging requirements, and desired capacity, the appropriate series can be selected to meet specific needs. The weight range for the flow wrappers is 0,1 to 2,5 kg and they can reach a capacity of up to 80 packs per minute.

Balers

Manter Balers pack consumer bags into durable paper, poly, or mesh master bags, efficiently counting each bag and sealing the master bag with glue, sewing thread, or heat seal. An optional vertical lift reduces fall height, enhancing the packaging process. These Balers can pack consumer bags up to 10 kilos and fill up to 9 bags per minute under optimal conditions. They offer an efficient solution for reducing storage space and optimizing logistics by allowing high, solid pallet stacks that are not possible with loose consumer bags, making them invaluable for large-scale packaging operations.