Agri Water Recycling

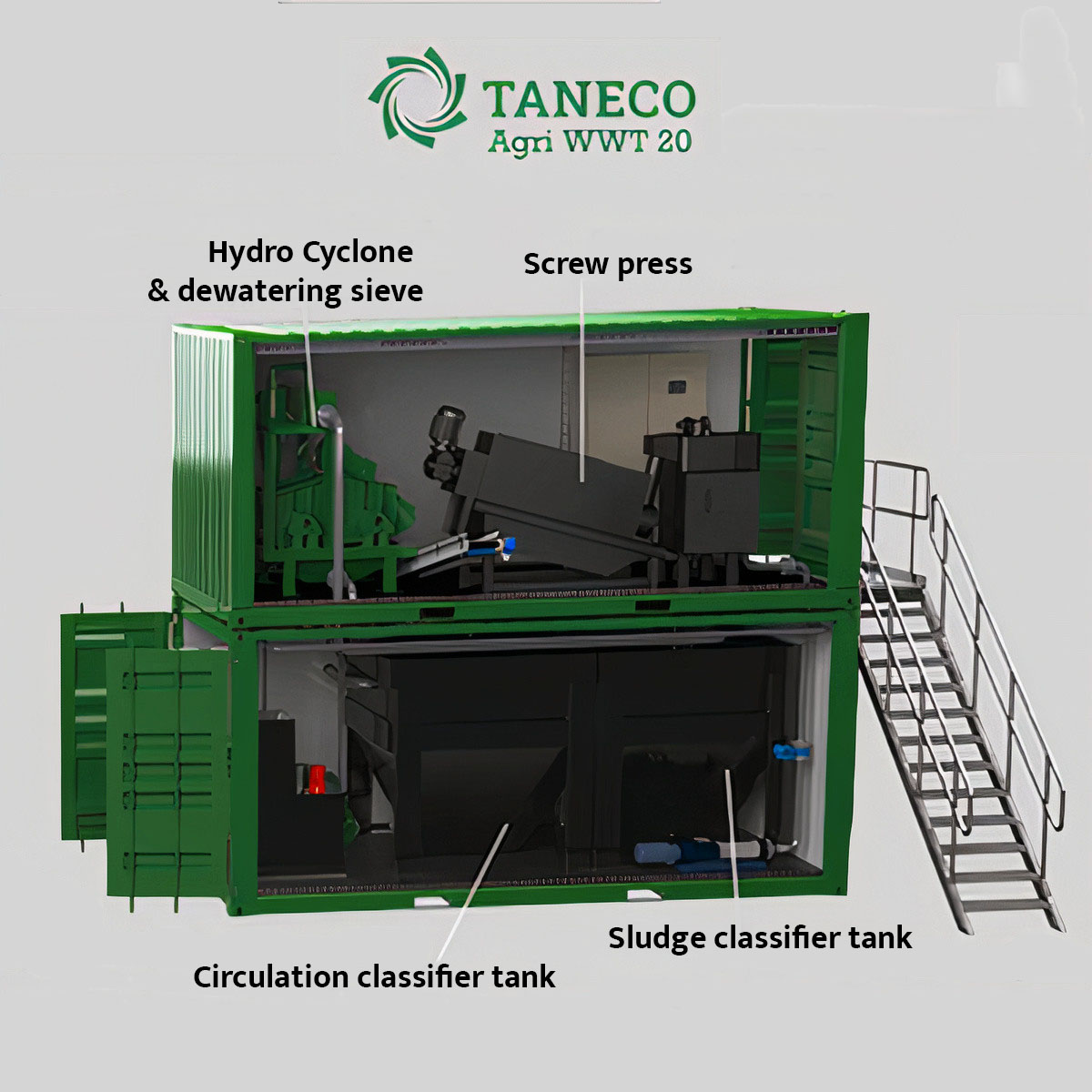

Taneco has the solution for potato and vegetable processors to recycle washing water in a simple, compact and financially attractive way. The Taneco Agri WWT installation treats washing water and saves up to 95% water. Water flows of 10 to 100 m3/h, which originate from washing potatoes or vegetables, are treated. The system is constructed in two 20ft containers stacked on top of each other, so less than 20m² of

space is required to place the installation.

The Taneco Agri WWT consists of the following components:

– Circulation classifier

– Sand recovery system

– Sludge classifier

– Sludge dewatering system

WWT10

The WWT 10 system is a verry complete system where sand and sludge are separated and dewatered. The system is build based on customer demands and capacities.

Technical details:

Capacity: 20 – 60 m3/h

Dewatered sand > 80% d.s.

Dewatered clay > 25% d.s.

Efficiency 98%

Bacterial removal optional

Sand separation and dewatering: Hydro-cyclones and separators are the ideal solution to separate solids from fluids. Therefore we use a cyclone to separate the sand from the rest of the wash water. The specially designed regulator ensures continuous results with varying loads. The sand will be dewatered with a Vibrating sieve

Sludge separation and dewatering: To separate sludge from wastewater, we use a Gravity Belt Thickener plus. The GBT plus is equipped with a press zone to dewater

WWT20

The unit is equipped with connections for wash water inlet, outlet and clean water. The wash water will be pumped to the circulation classifier. In the classifier sand will settle. The settled sand will be pumped over the sand recovery system, where it will separate particles bigger than 25 micron. A dewatering sieve dewaters these solids up to 75% dry solids.

Technical details:

Capacity: 10 – 50 m3/h

Dewatered sand > 80% d.s.

Dewatered clay > 50% d.s.

Efficiency 98%

Bacterial removal optional

The system is suitable for treating wash water from washers with 10-50 m3/h. The complete system is built in two 20ft containers

WWT30

The WWT 30 system is a sand separation system. In this case the client has verry little clay in the Tarra and decides to separate the sand only. Mostly supplied with extra buffers.

Technical details:

Capacity: 50 – 300 m3/h

Dewatered sand > 80% d.s.

Dewatered clay not seprated

Efficiency 25%

Sand separation and dewatering: Hydro-cyclones and separators are the ideal solution to separate solids from fluids. Therefore we use a cyclone to separate the sand from the rest of the wash water. The specially designed regulator ensures continuous results with varying loads. The sand will be dewatered with a Vibrating sieve.

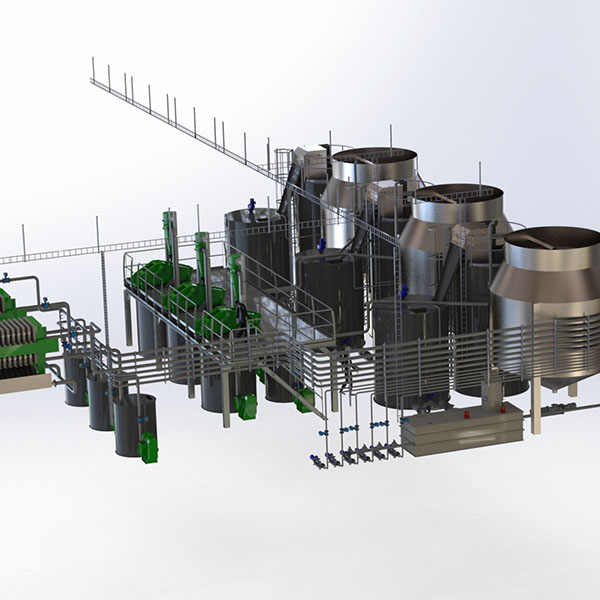

WWT40

The WWT 40 system is our most complete system where sand and sludge are separated en dewatered. The system is build based on customer demands and capacities.

Technical details:

Capacity: 50 – 300 m3/h

Dewatered sand > 80% d.s.

Dewatered clay > 50% d.s.

Efficiency 98%

Sand separation and dewatering: Hydro-cyclones and separators are the ideal solution to separate solids from fluids. Therefore we use a cyclone to separate the sand from the rest of the wash water. The specially designed regulator ensures continuous results with varying loads. The sand will be dewatered with a Vibrating sieve.

Sludge separation: To separate sludge from wastewater, we use a Gravity Belt Thickener or a lammel filter.

Sludge dewatering: To dewater the sludge from the GBT/Lammel filter we use a decanter. The decanter will dewater the sludge to a minimum of 50% dry solids