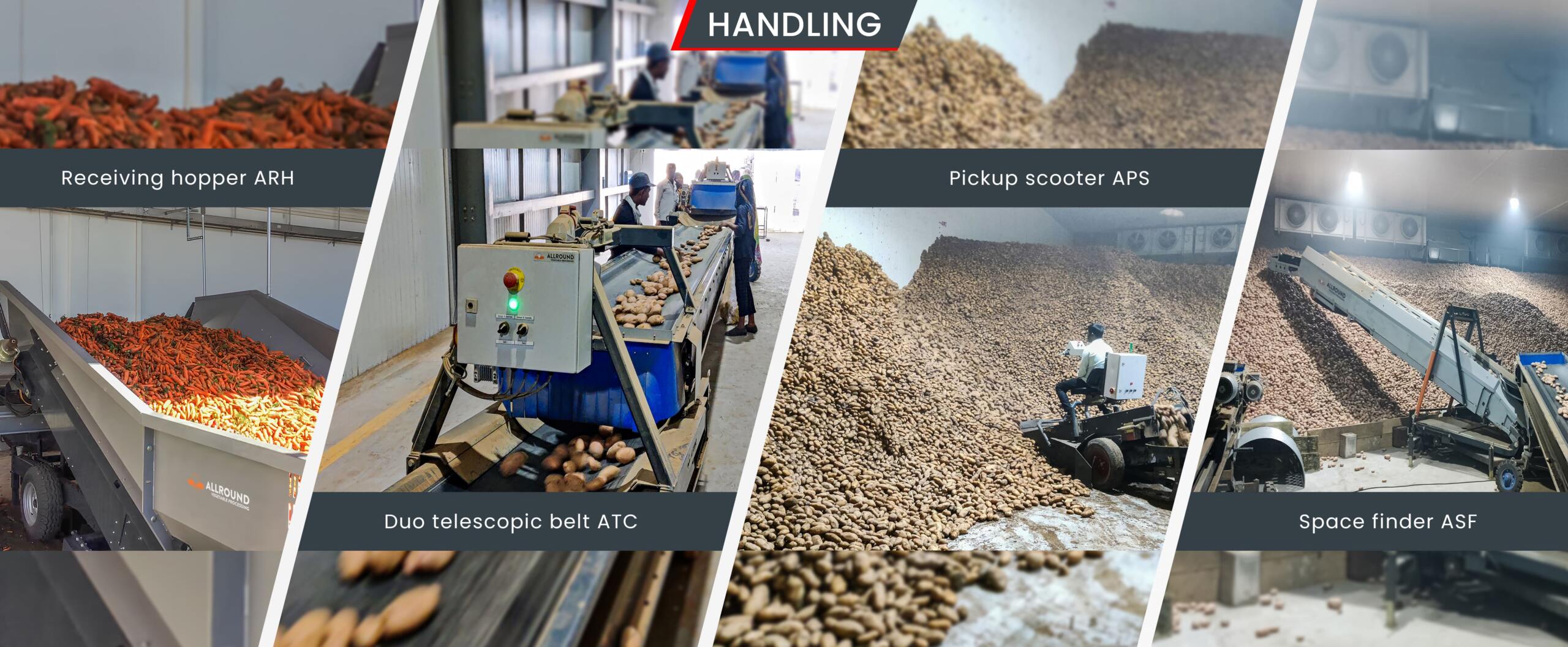

Handling

Our handling technology for infeed and outfeed of potatoes, onion red beet etc has already found its way to more than forty countries. The machines are produced at our site in India. In most large potato projects in India, Allround’ infeed and outfeed lines are used. For box storage we have a full range of box fillers. We are aware that the handling equipment must not break down when it is used. The storage of the product during the harvest is a very critical moment where no malfunctions and delays should take place. At our head office in Ambala and our sales and service points in Ambala and Ahmedabad, we have all the necessary parts in stock. Our local service technicians are at your service immediately. When an accident unexpectedly occurs, we can respond very adequately. Allround handling equipment is robust, reliable and easy to operate.

Receiving hopper

The Allround receiving hopper is designed to feed or act as a buffer in loading and unloading lines in cold storage or processing lines. The hopper is designed in such a way that it can be fed by tip trailers, box tippers, and big bags. Because of the angle of the machine, the flow of the product will always be even. Furthermore, a frequency inverter is fitted to the machine, to make sure the flow of product is always adjustable.

After the machine is filled, a belt transports the product diagonally up towards the outfeed. A dosing sensor detects how much product is on the belt and adjusts the output rate of the hopper accordingly (automatic capacity control).

The outfeed of the machine is designed with a knick so that the product lands gently over the transport conveyor. The machine is provided with wheels so that it is easy to relocate the machine in a shorter distance. The machine is available in options with no straight part or with 1000mm, 2000mm, and 3000mm to suit various feeding methods.

Duo Telescopic Belt ATC

The Allround duo telescopic belt is designed to facilitate the loading and unloading of products in storage facilities. The belts are usually placed behind a spacefinder or pick-up scooter and is designed in such a matter that the whole storage facility can be utilized.

|

Min. Length |

8000 mm |

|

Max. Length |

14000 mm |

|

Belt width |

800 mm |

|

Conveyor length |

2 x 7500 mm |

Pickup Scooter

The Allround Pick Up scooter APS 250 is designed to empty bulk storage facilities. The bulk stores are cleared by the Pick Up scooter by scooping up the produce. There is one driver needed, who will be working in comfort.

Optionally it is possible to add the pickup scooter and Duo belt. The Allround Pick Up scooter APS 250 is designed to empty bulk storage facilities. The bulk stores are cleared by the Pick Up scooter by scooping up the produce. There is one driver needed, who will be working in comfort.

Space Finder

The Allround Space Finder is designed in such a way that bulk stores are filled in the most effective manner. The Space Finder makes sure every inch of the storage facility is used.

|

Belt width |

600 mm |

|

Minimal length |

6350 mm |

|

Maximal length |

9500 mm |

|

Maximal discharge height |

5400 mm |

|

Swing reach |

13000 mm |