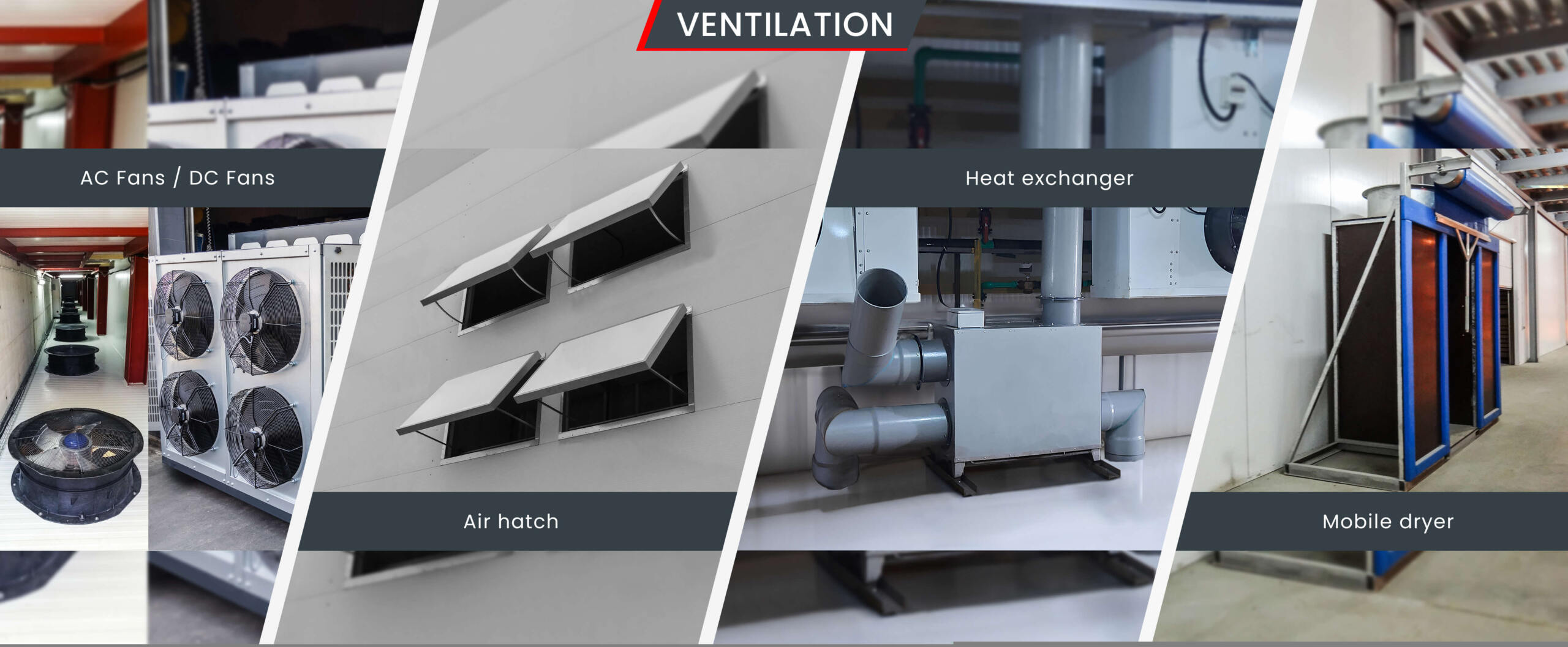

Ventilation

At Allround, we work with three systems for ventilation. The first is direct ventilation in the form of bulk storage. The air will be forced through the product by so called perforated ducts. The second category is cubic box room ventilation. Here we use indirect ventilation by means of natural convection. Warm air goes up and cold air goes down, creating a natural constant circulation. The third way of ventilation is bags in racks. These racks are located in a room. A more detailed explanation is at he page storge for products. So not as with the traditional way of storing bags in different floors. We at Allround do not sell traditional bag storage systems. We do not consider this way to be optimal. The ventilation can never work optimally, so the storage will also leave much to be desired. __partners are prominent suppliers for the potato process industry. In principle, the lines and technology of Allround and partners are separate from the actual frying line. Allround with the Partnership of Companies is therefore compatible with any producer of French fries, chips or whatever. However, we can offer internal transport for you for each project, installation or single line. Below is a brief overview of our delivery program for potato processing projects

Bulk ventilation:

- Cooling capacity 80 W/t for potato / onion.

- Air capacity 80 m³ per m³

- 1 m³ potato = 650 kg

- 1 m³ onion = 550 kg

- Bulk height = 4 m

- Room size 1000 mt potato = 400 m² (20 x 20 m)

Room ventilation:

- Cooling capacity 80 Watt for potato / onion. 100-120 W/t for carrots.

- 1 Recirculation fan per 200 t

- For potatoes carrots 1 x Humidifier per room.

- For onions 1 x Refrigeration drier per room.

- Standard box dimensions 1600 x 1200 x 1230, 5 stack high.

- 1 box potatoes 1150 kg

- 1 box onions 1000 kg

- Roughly 0,5 m² needed per t potato

- Roughly 0,6 m² needed per t onion

AC/EC Fan

Fans are an integral part of the storage system, and therefore it is very important the proper type of fans are chosen for the right application. Furthermore, fans should be reliable and able to work under difficult circumstances. Our fans are designed especially for agricultural applications.

Components

• Cast aluminium fan blade

• Ring made of galvanized steel

• Ring shape is designed to prevent turbulence

Air Hatch

Ventilation with outside air requires air inlet hatches and consequently air outlet hatches. The air inlet hatches are located near to the fans and are used to create an optimal mix between internal and external to achieve an optimal air flow to the product.

Allround produces the hatches in their own factory.

Made of:

- Flap made of first class PIR sandwich panels

- Very durable and weather proof sealing rubber

- Galvanized steel frame and hatch cover

With the help of a mixing box construction around the air inlet hatch, the amount of internal and external air can be regulated. The storage controller knows the ideal conditions of the air that is required by the produce. By opening the hatches with pulses the hatch will be placed in optimal. The length of the pulse depends of the outside temperature. When it is very cold the pulse will be short to avoid too cold air entering the store.

Heat Exchanger

All kind of stored agricultural products are sensitive for too high CO2 levels. Too high CO2 levels can affect the quality of the product. For example during storage of industrial potatoes, high CO2 levels can affect the frying quality. In systems where a lot of outside air is used, it is not so difficult to control the CO2 level. In hot climates, or very cold climates where use of outside air is limited, a CO2 heat exchanger will be the best solution. In warm climates outside air cannot be applied directly since this will cause an increase of the product temperature. With the help of a heat-exchanger the extracted cold air from the storage room with high CO2 level is applied to pre-cool the warm outside air with low CO2 level. In this way energy savings up to 90% can be achieved.

Components

- Control panel

- High efficient heat exchanger

- Western Europe fans used

- Housing made of galvanized steel

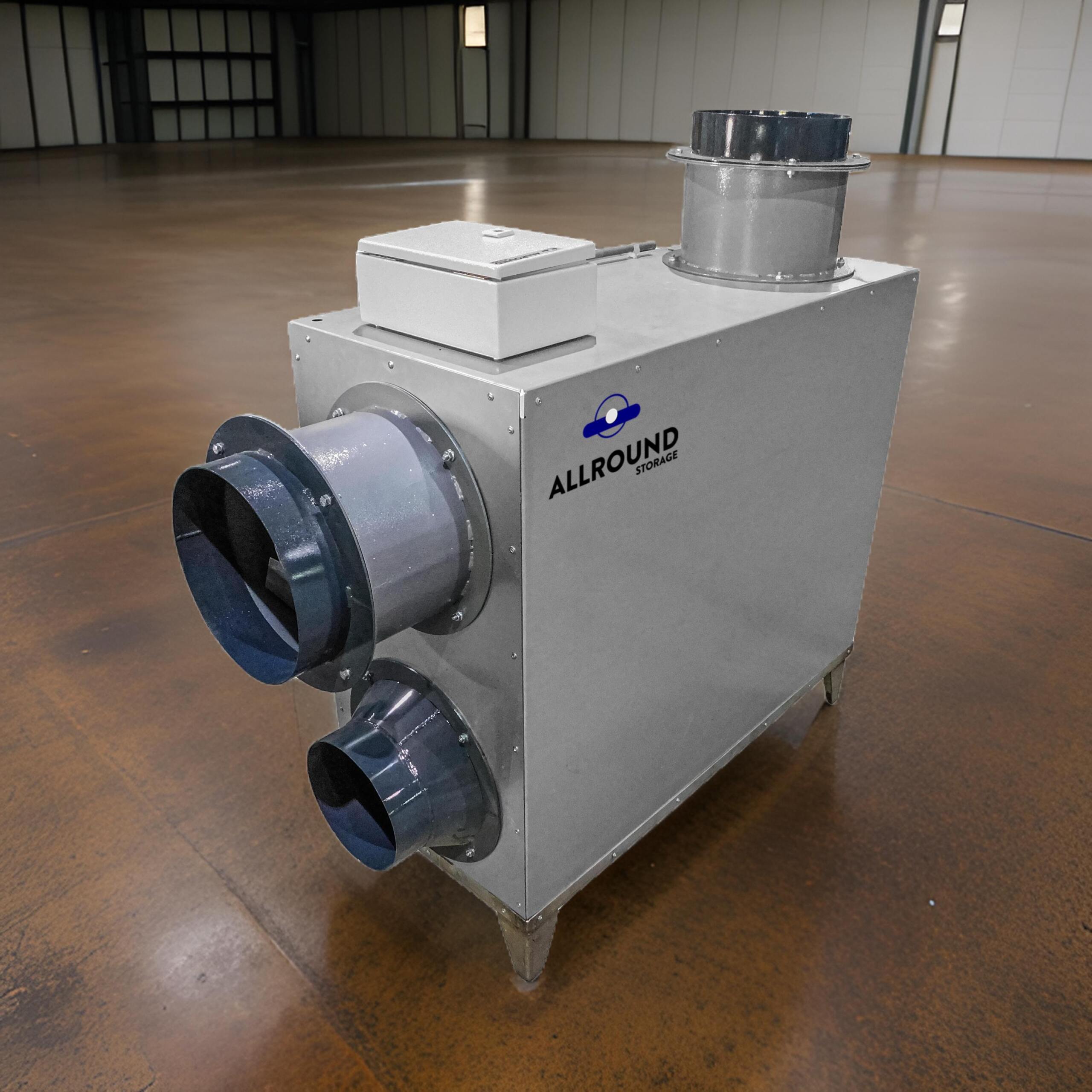

Allround Potato Decondensation Unit (PDU)/ Mobile Dryer

When the potatoes come out of storage and come into contact with warm outside air, the potatoes start to condense. The warm outside air collides with the cold potato, causing it to condense. This means that the potatoes need to be warmed to the dewpoint. When this value is reached, condensation no longer takes place and the potatoes remain dry. Also this warmed up potato is much more resistant agains any damage during further process. In the traditional way, the potatoes are thrown on the ground under a roof and then let them heat up. A lot of damage takes place in this way. The cold potato is very sensitive to bruising. With the Allround PDU, the potatoes are dumped in a cubic box. This cubic box is closed on the sides. Then we close the last box with foam at the front. In this way, the air is forced out through the product in the boxes. This method of forced drying has been used for decades in bulb cultivation in the Netherlands. Allround has been selling the PDU in India since 2010. The experiences have been very positive. The investment is relatively small. Allround Potato Decondensation Unit. PDU