Retail / E tail

n India and other countries in Asia, the Middle East and Africa, the retail channel is developing more and more towards sales through supermarkets. Selling high-quality and beautifully packaged potatoes, fresh vegetables and fresh fruit is essential for supermarkets to differentiate themselves from the street trade. Other categories for retail are, hospitality such as restaurants and hotels. The third important category that we distinguish are the institutions such as school canteens, hospitals and company canteens. For a good logistical and smooth and efficient way of trading between the packers and suppliers (growers), new ways of selling must be developed. Electronic trading platforms that require fewer actions and are therefore more sustainable. Over the past twenty years, Allround has developed into a specialist in the design of complete packing houses for potatoes, fresh fruit and vegetables. In these designs and ideas, all six criteria, as explained on this website, are discussed in detail. We are aware of the latest developments worldwide. We have an extensive network of suppliers for special packagings and packaging machines. Together with large parties in India, we have developed weighing and packaging lines. For this we paid particular attention to staff training, easy operation, relatively low purchase price and good after sales.

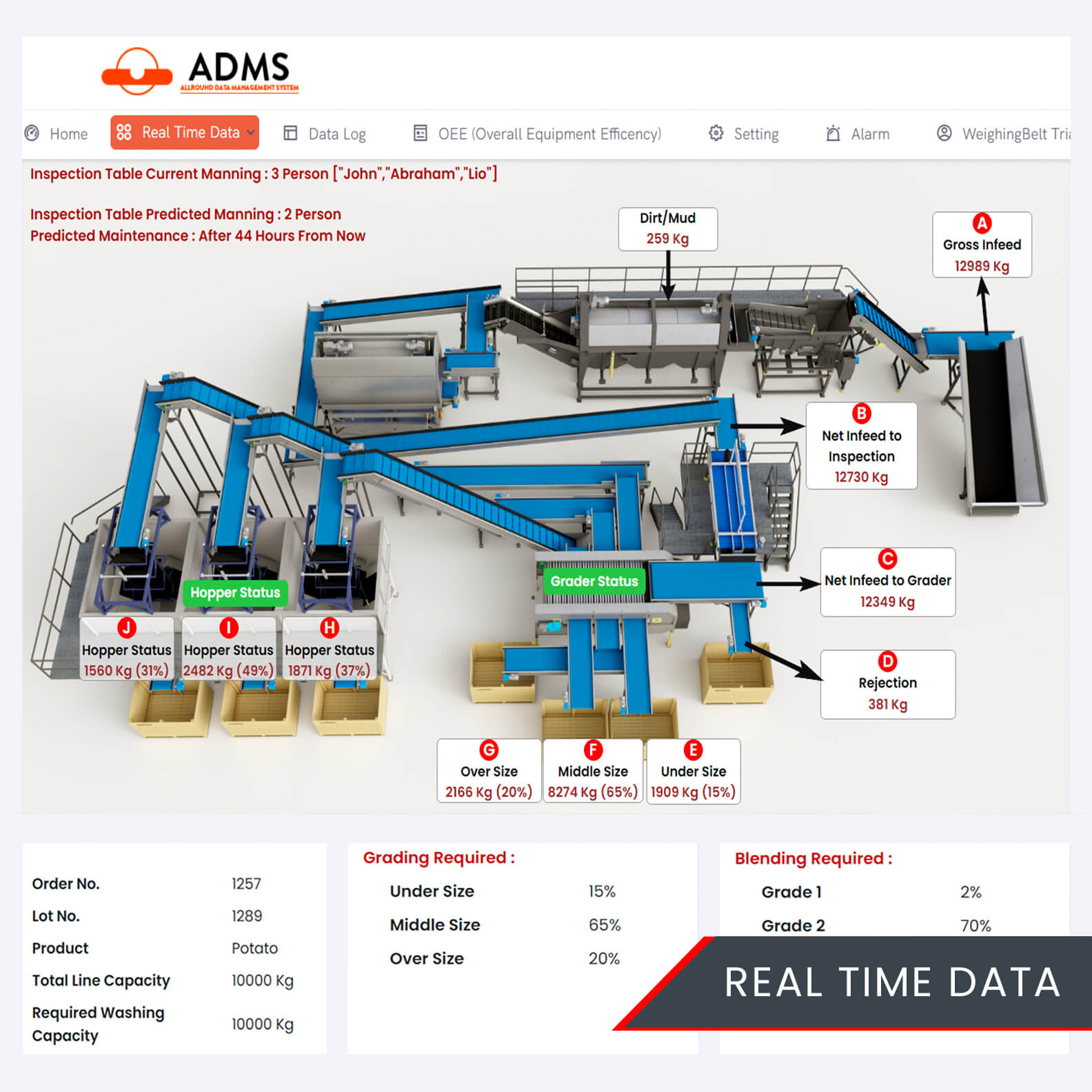

Receiving , pre cleaning, washing, sorting and grading

Allround has an extensive range of machines and complete lines for cleaning, sorting and grading potatoes, carrots, onions and related products. We have lines from 2 tons per hour to a hundred tons per hour. A detailed overview of both lines and single machines can be found on the website of: www.allroundvp.com

Product range for retail for washing, sorting and grading lines.

- Box tippers.

- Receiving hoppers.

- Pre cleaning sets Blank rollers, spiral rollers, spiral with blank rollers & finger rollers.

- Washing machines. From 1 cubic meter content till 18 cubic meter content.

- Onion toppers. Optional with pre grading.

- Sorting tables. Roller inspection and flat belts.

- Grading machines. Radial grading shake grading machines, web graders.

- Leaf separators

- Evenflow Hopper

- Dust extraction.

- Water purification systems.

- Internal transpor

Weighing and packing lines

Each country has its own specific way of selling fresh vegetables, potatoes and fruit. In the retail channel, a lot of sales are pre-packaged. For smaller packages from 1 kg to 5 kg, we work with multi head weighers from Manter. Multi head weighers have a big advantage that you give away much less excess weight to the customer. Example calculations on the website. We at Allround India can show you examples of packaging from all over the world. In addition to the multi head weigher, we also have manual weighing and packaging lines. These lines are cheaper to purchase and easier to operate.

- Receiving hoppers.

- Elevators.

- Evenflow hopper. To ensure a continuous weighing and packing process.

- Multi-head weighers. From eight heads to sixteen heads. From 1.8 kg per 12g pack

- Just like packaging machines. For sleave net from 1 kg to five kg.

- Poly bag packaging machines from 1 kg to 5 kg and from 5 kg to 18 kg.

- Paper dredge. For packing potatoes in paper bags.

- Dust extraction. On the weigher and in front of the clipping machine. Is necessary so that clipping machines do not malfunction.

- Turning tables for collection.

- Check weighers.

Saving by multi head weigher

| Comparison | Multi-Head Weigher (Manter Type M8) | Manual Packing |

|---|---|---|

| Packaging Weight | 1 kg | 1 kg |

| Capacity | 1.8 tons/hour (1800 packs of 1 kg) | 1800 packs of 1 kg |

| Overweight Percentage | 2% to 3% (average 2.5%) | 8% to 10% (average 9%) |

| Overweight in kg per hour | 1800 x 2.5% = 45 kg | 1800 x 9% = 162 kg |

| Hours Worked Per Year | 15 hours x 48 weeks (6 days) = 4320 hours | 15 hours x 48 weeks (6 days) = 4320 hours |

| Total Overweight Per Year | 45 kg x 4320 hours = 194,400 kg | 162 kg x 4320 hours = 699,840 kg |

| Total Savings in Overweight | 699,840 kg – 194,400 kg = 505,440 kg | – |

| Cost per kg (INR) | INR 7.5 | – |

| Total Savings (INR) | 505,440 kg x INR 7.5 = INR 3,790,800 | – |

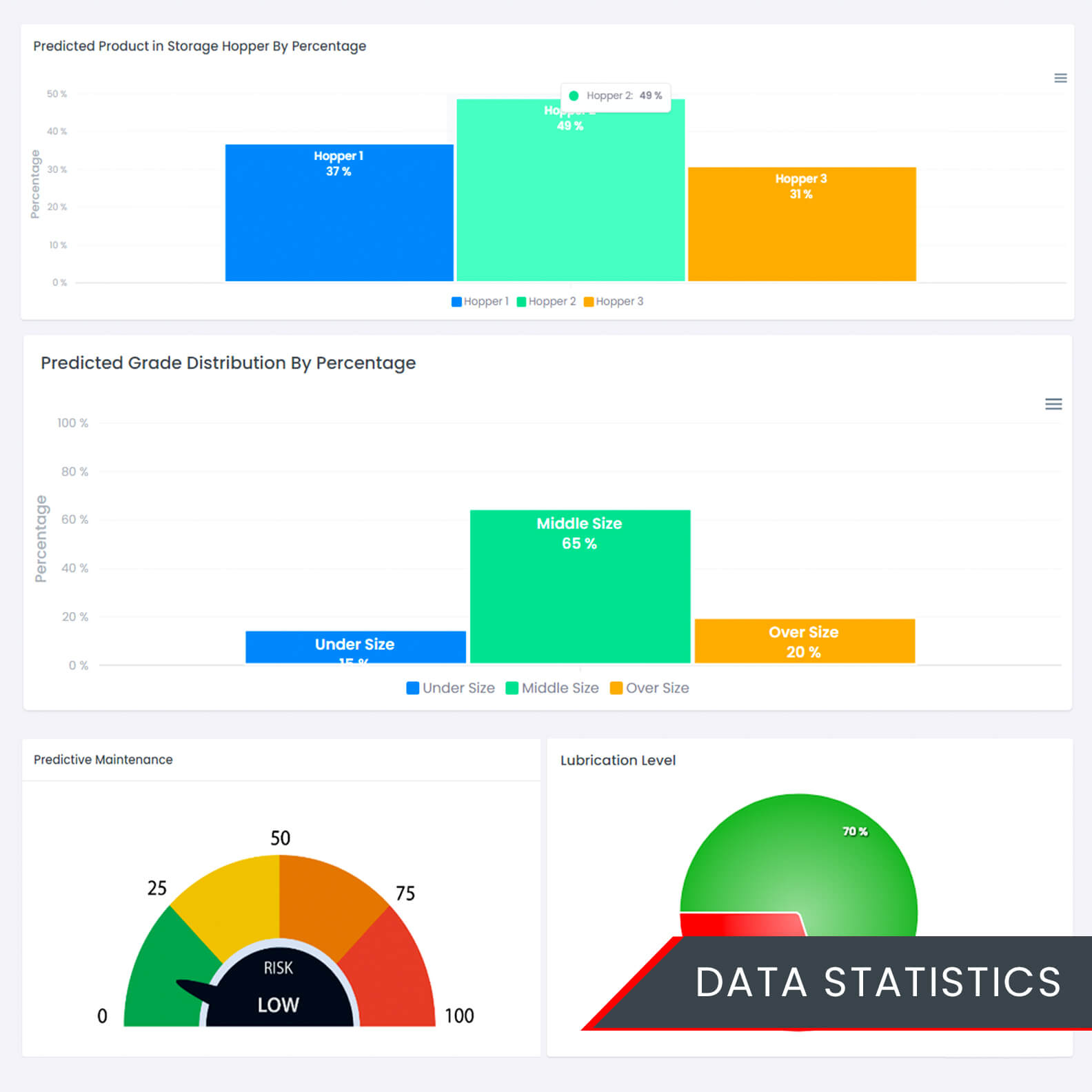

Management tools. Control RIF for labor Track and trace system CCTV

We regularly have projects for very different products in the process industry. We work with several suppliers of electronic sorters. We then supply the supply and discharge of these machines. Below is a very limited selection of machines that sell as single machines in the process industry.

- Weeg banden. Excellent management tool.

- Flat conveyor belts.

- Product shears.

- Modular belts.

- Modular curved tires.

- Elevators.

- Organic waste separators.

- Box transporters.

- Box fillers.

- Many on request.